Avoiding Costly Downtime: Essential Equipment Maintenance for Small Businesses

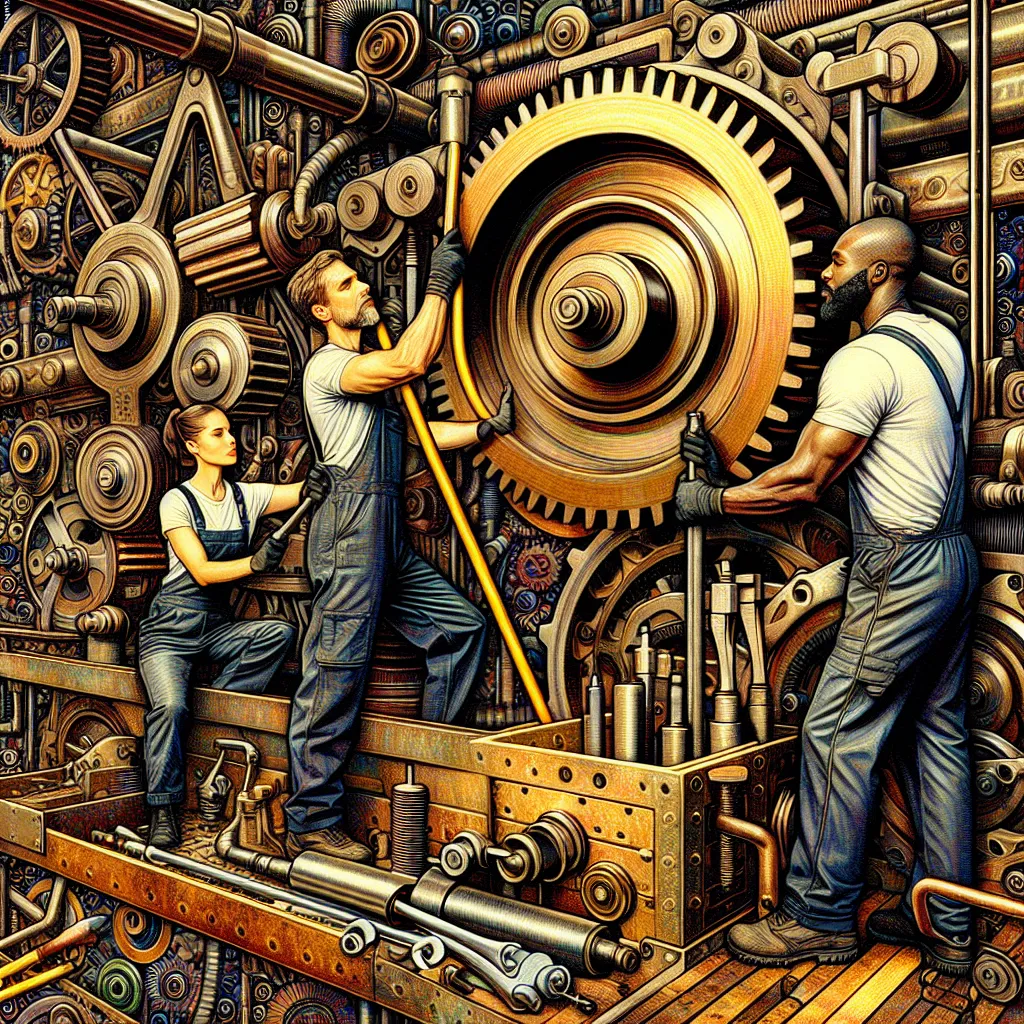

The article “5 Key Equipment Maintenance Strategies for Small Business Owners” delineates essential strategies to ensure the smooth operation and longevity of business equipment. It emphasizes the significance of regular inspections, preventive maintenance programs, employee training, documented maintenance records, and the utilization of technology to streamline maintenance processes. By integrating these strategies, small business owners can mitigate costly downtime, prolong equipment lifespan, and enhance overall productivity and efficiency, underscoring the crucial role of proactive maintenance in business operations. Additionally, the related guide “Maximizing Uptime: A Guide to Preventative Maintenance for Small Business Equipment” underscores the importance of adhering to manufacturer’s guidelines for equipment upkeep, investing in a computerized maintenance management system (CMMS) for streamlined maintenance tracking, and regular training of staff members responsible for equipment operation and maintenance. Prioritizing preventative maintenance can effectively maximize uptime, minimize costly downtime, and prolong the life of equipment, highlighting the proactive approach as essential for small business success.